- Home

- Products

- Hookloader and Skiploader

- Technology Lines

discover our lines

OPEN POSSIBILITIES TO MEET THE CUSTOMER NEEDS

The SLD and TEC lines are featuring different performance levels and offering a wide range of functions and solutions while preserving the payload. These lines bring with them the possibility to meet the customers’ needs as closely as possible, with clear differentiation according to technical features. The hookloader is always designed for easy installation on the truck while keeping an optimized dead weight.

V DRIVE

VERSATILITY AS A KEYWORD

At the cutting edge of controller technology, the V DRIVE offers intuitive day-to-day operations. The versatility of the screen allows to manage all your options, connected systems and accessories from a single controller. Benefit from all functionalities in a compact and ergonomic item with a smart design.

With 5 screens and dozen of possibilities to adapt the icons to the exact functions, the V Drive cab controller is the most complete and flexible tool of our offer. Its intelligent conception ensures its ability to remain up to date and ready for future changes in requirements and the addition of new functionalities.

The V Drive is the result of many years of experience and close attention to the customers uses and habits. Intuitiv with a good tactile answer and functionnal design, the cab control will be the new standard for the TEC line. The best part of it is ist flexibility with 5 different screens adapted to the handling phase, applications and the driver‘s habits.

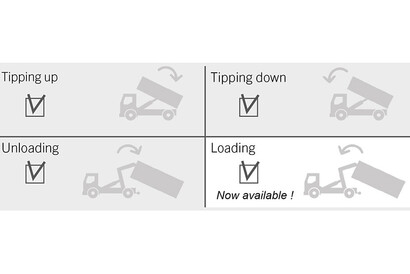

VERSATILE MODES

Select the mode you want to operate, the relevant screen will be displayed and the functionalities of the side buttons will be adapted.

FUNCTIONAL DESIGN

Tailor-made to allow intuitiv hookloader controls

VISIBILITY OF INFORMATION

Colored and large icons providing live status feedback. High degree of graphical customization for specific functions.

ERGONOMIC CONTROL

One single lever to control precisely all container movements.

The TEC is the right choice when owners and users need to improve the configuration of their equipment.

Whether the priority is to make daily work easier and more efficient, to increase safety or to work as comfortably as possible, PALFINGER constantly seeks to provide state-of-the-art solutions by offering several options to upgrade equipment throughout the complete life cycle. Add a concentrate of PALFINGER’s hookloader expertise from the outset of ownership or later through retrofit.

It can be to adapt the hookloader to a very specific use in agricultural application or handle containers with a full flexible product and thus ease adaptation to different jobs like in renting companies. With the TEC line, open possibilities and pick up the options created for your needs.

Take advantage of the standard TEC features and add optional ones to improve the daily job depending on the needs.

Packages of options have been created to benefit from the equipment with performance and comfort in mind. Close to the customer needs, they simplify the configuration process gathering the options depending on the priorities.

A specific package, dedicated to e-trucks is also offered to fully benefit of their specificities

PERFORMANCE PACKAGE: When speed and precision are required

• Rapid Motion

• Automatic Cycle

• Proportional speed

COMFORT PACKAGE: For the perfect view from the driver seat

• System monitoring

• Automatic cycle

• Proportional speed

E-TRUCK PACKAGE: For optimised noise reduction

• E-PTO control via CANbus

• Proportional speed

• Silent mode

• Soft sliding

CUTTING EDGE OPTIONS

The system monitoring option has been developed to allow a better control of operations from inside the cab. Drivers can see accurately and without effort, what they are doing, thanks to cameras displayed on the touch screen. The automatisation of cam selection smooths the operation and allows it to stay focused on the handling, to be able to react immediately if needed. The screen allows also to show live status information (position of equipment and locking devices, error QR code and status of the sensors).

- Increases safety of the working area

- Eases the turnover of users - improves familiarization with the machine

- Improves profitability of your equipment

- Improves the focus on tasks

- Improved efficiency through the sharing of fast, clear information

Whether it's to keep a sleepy street quiet or to reduce the sound level of a noisy site, the new "Silent mode" option can improve working conditions while maintaining a high level of safety.

When the option is activated, the traditional buzzer is replaced by three flashing lights to warn of possible arm movement. The lights are strategically placed around the hookloader for maximum visibility: one at the front and two at the rear. The safety of the work site is preserved and the operator handles the containers in better conditions.

Thanks to the memorization of the "silent mode" configuration, it is not necessary to reactivate it each time the machine is started. This means that there is no risk of an unwanted sound signal.

With the increasing electrification of vehicles, this option makes complete sense. When the engine is silent, it is even more important to maintain these pleasant working conditions when the hooklift is in use.

Benefits

• Any surrounding persons are clearly warned by the vehicle

• The driver can work in much better condition

• Neighborhood is not annoyed by the noise emission

• Perfect for electrified trucks