PR cranes

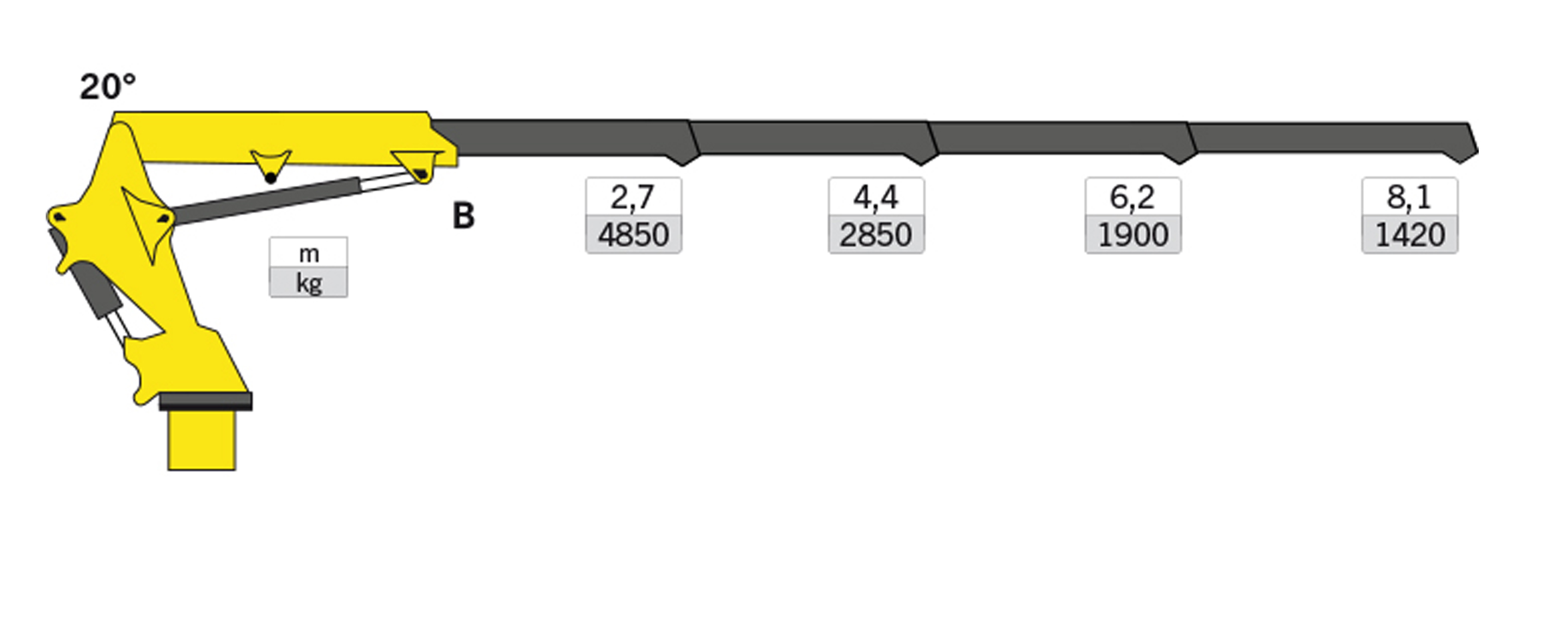

PR 120

PR 120

Unbeatable - in tight spaces where no other crane concept can be used. On one side, an activated lateral movement limiter, on the other side, an extremely close and tall noise barrier, along with the live overhead line and the height limiter activated? No problem with the PR crane! With it, the entire loading area can be loaded and unloaded, and loads can be picked up and set down in front of and next to the vehicle. With their special kinematics, PR cranes offer completely new possibilities for use and fundamentally simplify construction site logistics.

- Slewing within the profile

- Autonomous mounting of counterweight and crane operator's cab

- Optimal coverage of the loading area

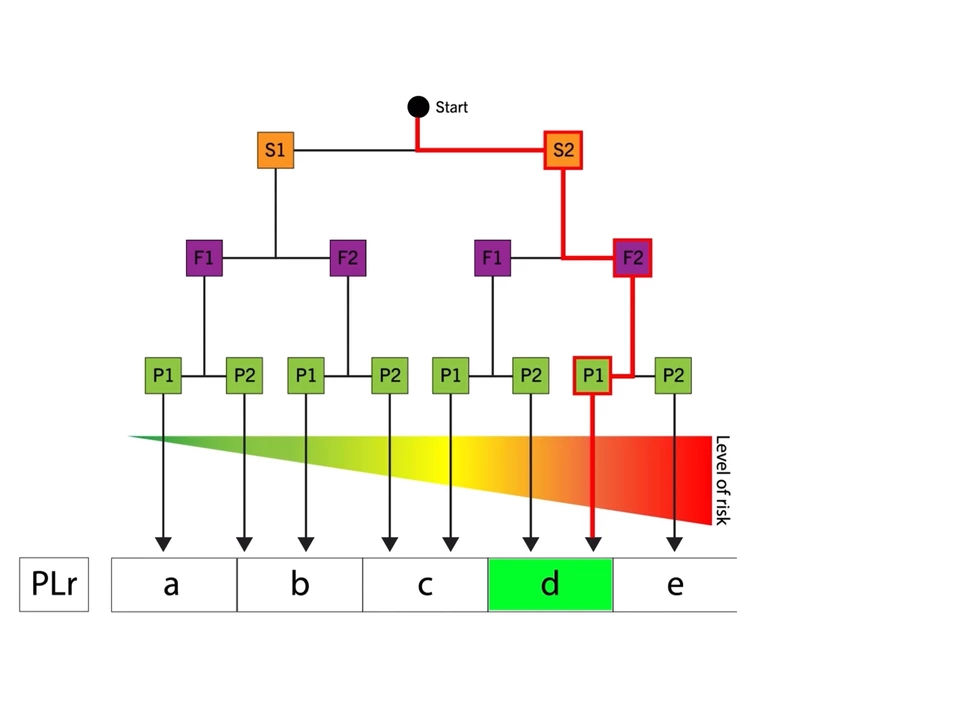

- PLd-compliant control system according to EN13849

- Secure data transmission according to the CANopen Safety Protocol

- Combined operation of more units mounted on the same vehicle

- Safe operation through lateral and vertical movement limiters according to EN 14033

- Versatile range of applications due to a large pool of crane attachments

- Efficient and fast due to continuous slewing gear

- High user-friendliness through radio remote control

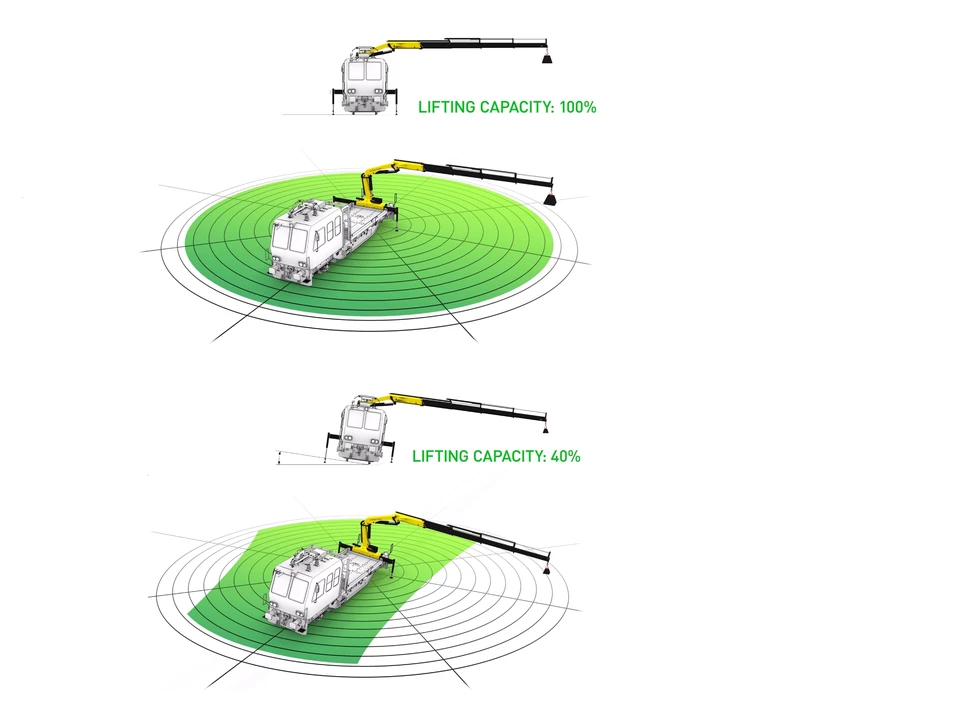

Slewing within the profile

Its special tiltable crane column gives the PR crane a small slewing radius and allows for slewing within the profile.

Unmatched in the trackside area

The PR crane stands out in the trackside area due to its unique features. Despite live overhead lines, the PR crane positions all loads in close proximity to the vehicle, thanks to its exceptional kinematics.

Autonomously detachable counterweight

For heavy-duty operations, the counterweight of the PR crane can be mounted and detached thanks to its exceptional kinematics by the crane itself. It enables performance improvements of up to 30 percent in terms of vehicle stability. For work without support legs, the counterweight is the perfect add-on for heavy lifts.

Removable crane operator cabin

The crane operator cabin BH258, specially designed for the PR crane, can be independently installed and deinstalled by the crane itself. The challenge of mulching work in the trackside area is effectively resolved for the crane operator

State-of-the-art technology in the crane operator's cabin

The newly developed cabin control allows for the effortless execution of complex work tasks. In addition to controlling the crane movements, the vehicle's drive can also be operated using the foot pedal

Earthing

With the earthing of all components through highly flexible grounding cables, PALFINGER provides perfect protection against electric shocks. All components - from the base to the crane tip - are connected by 2x50mm² strong grounding cables. Transparent insulation material facilitates the inspection of grounding cables for breaks or damage caused by derived current (carbonization). Devices with a work basket are also equipped with grounding cables.

KombSmart Control System Ensures Stability by Balancing Overturning Moments of Crane and Access Platform

The combined use of PALFINGER railway devices achieves the highest efficiency. With its flexible adjustment method, PALFINGER enables the operation of multiple devices on one vehicle. The existing vehicle stability moment is perfectly distributed through communication between the devices.

Continuous lifting capacity optimization in inclination

The strengths of PALFINGER railway cranes come to the fore in operations at high track cants. State-of-the-art sensors incorporate the inclination in real time into the stability calculation. This allows the crane's lifting capacity to be continuously adjusted from 0° to 15°, eliminating the need for reducing I in general.

Vertical Movement Limiter according to EN-14033

The parametric Vertical Movement Limiter of the Railway Premium Line allows maximum range of motion with the highest level of safety. The limit-curve according to EN14033 is calculated based on specific track parameters and safety measures. To prevent safety-compromising movements, Paltronic dynamically detects the crane's position in real time using state-of-the-art sensors. With an extension, up to three height limit-curves can be stored in Paltronic.

Lateral Movement Limiter according to EN-14033

The parametric Lateral Movement Limiter of the Railway Premium Line allows maximum freedom of movement with the highest level of safety. The limit-curve is calculated based on the specific clearance profile and corresponding safety measures according to EN14033. State-of-the-art sensors combined with Paltronic ensure a PLd standard. With an extension, up to four different limit-curves can be stored in Paltronic.

Performance Level according to ISO 13849-1 is PLd

The Paltronic crane control system, combined with the connected sensor system, achieves Performance Level PLd and meets the high safety standards of railway norms.

Brochures

You are currently on the PALFINGER Europe page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?