Medium

PK 23002 SH High Performance

- Go back

- Home

- Products

- Loader Cranes

- Models

- PK 23002 SH High Performance

PK 23002 SH High Performance

Construction sites that are difficult to access and tight schedules. This is where Power Link Plus and the continuous slewing system really deliver.

- High value retention thanks to coating technology

- More comfort and safety due to Soft Stop

- Maximum utilisation of the working range due to HPSC

- More lifting power due to S-HPLS

- More efficient and faster due to continuous slewing

Continuous Slewing System

The PALFINGER Continuous Slewing Mechanism permits an unrestricted radius of action. The crane is rotated or 'slewed' using a gear box and hydraulic motor instead of a rack and pinion system. All endless slewing mechanisms come as standard with a high quality roller ball bearing.

Folding Assist

Efficient and Safe – The new FOLDING ASSIST function for your LOADER crane

Save time and minimize the risk of damage: With the new FOLDING ASSIST function, you can semi-automatically find the exact position for folding your loader crane. The assistance mode guides you precisely to the correct slewing position, from where you can manually fold the loader crane safely and quickly. No more lengthy searching –

for greater efficiency and safety in every operation.

Low-maintenance extension system

With sliding elements made of synthetic material and the high-quality KTL coating, this boom system significantly simplifies service performed by the operator. This saves time and money – and protects the environment.

Power Link Plus

The PALFINGER Power Link Plus system is a double linkage system with a linkage on the knuckle boom and a linkage between the main boom and crane column. With the 15 degree reverse linkage system, reaching through low door openings or working inside buildings is no problem.

High Power Lifting System

The PALFINGER High Power Lifting System (E-HPLS, A-HPLS or S-HPLS) increases the capacity of the crane by up to 15% while reducing working speed. E-HPLS can be activated manually for the occasional manipulation of very heavy loads. A-HPLS as well as S-HPLS are activated fully automatically. There is continuous activation depending on the power required.

Soft Stop

The Soft Stop function is an electronic limit position damper. It causes gentle braking of all crane movements before the limit position is reached. Hence, jerky movements and load impacts can be avoided. The crane can be operated more gently and precisely.

Experience the product features

KTL

PRODUCT FEATURES

The right surface treatment is the foundation for durable and long-lasting surface protection. The components pass through the priming and painting process stages fully automatically. Through this innovative technology for surface coating, PALFINGER creates a quality standard that is usually only found in the automobile industry.

HOW IT WORKS

1. The crane components are cleaned of all impurities by means of cut steel shot blasting.

2. The components are degreased, rinsed, activated and coated with zinc phosphating in the individual immersion tanks.

3. After two additional rinsing processes, the surfaces are passivated as well as rinsed with ultra-pure water.

4. The electrostatic cathodic dip painting follows by immersing the crane components completely in the paint.

5. Excess paint is washed off in two additional operations with an ultra-filtration rinse.

6. Afterwards, the paint is cured at a temperature of 115 degrees for 1.5 hours.

7. At the end, the crane components are given a water-soluble, environmentally friendly two-component finish coat of paint by a painting robot.

Paltronic 150

PRODUCT FEATURES

With the PALTRONIC 50 and PALTRONIC 150, PALFINGER offers the latest control electronics for the series production crane. The most important safety and comfort functions include:

- overload cut-off

- stability control (HPSC)

- High Power Lifting System (HPLS)

- Active Oscillation Suppression system (AOS)

- Dual Power System plus (DPS plus) in the fly jib insert

HOW IT WORKS

The PALTRONIC controls and monitors the crane.

- Pressure sensors on the cylinders send information on the capacity utilisation of the crane to the PALTRONIC.

- Position sensors send information on the position of the boom system, the slewing gear or the stabilizer support to the PALTRONIC.

Based on the incoming signals, the PALTRONIC decides on shutting down or activating systems.

HPSC

PRODUCT FEATURES

The High Performance Stability Control (HPSC) is a fully proportional system for monitoring the stability of the crane vehicle. Sensors for proportional path measurement in the stabilizer supports permit completely variable support positioning. Hence, the permissible, safe working range can be calculated for any support situation.

HOW IT WORKS

The HPSC system calculates the permissible working range for any slewing angle of the boom system and for any support situation. The position of the stabilizer support is detected by means of a cable extension transducer or magnetostrictive position sensor. Based on the intelligent calculation algorithm developed by PALFINGER, it works more efficiently than comparable systems that are available in the market.

* Optional feature/country-specific-equipment

AOS

PRODUCT FEATURES

The patented PALFINGER "AOS" oscillation suppression system cancels out vibrations and blows that occur during crane operation. Any "post-oscillation" is prevented through rapid braking or load changes. The result is a decisive increase to safety in crane operation for employees, the load and building.

HOW IT WORKS

The electronics receive signals from pressure sensors on both sides of the elevating cylinder and interpret them as arm vibrations. The signals for the counter-movement of the elevating cylinder are handled by the control valve. The incurred vibration can be cancelled through the exactly determined frequency and wavelength. The result is damping of the arm to just one or two short vibrations so that the arm comes to an immediate standstill. Patent granted

* Optional features/country-specific-equipment

Radio Remote Control

PRODUCT FEATURES

Today, radio remote controls are often considered to be standard equipment when it comes to modern loader cranes. PALFINGER radio remote controls are equipped with a choice of a linear lever or cross lever and provide the greatest possible comfort of the operator. For cranes with PALTRONIC an LCD graphic display or 4.1 inch TFT- colour display informs the crane operator of the different operating conditions.

HOW IT WORKS

The remote control console (transmitter) is responsible for transmitting the commands made on the levers to the receiver. The receiver forwards the signals to the electronics, which convert them into crane movements by means of hydraulic control valves.

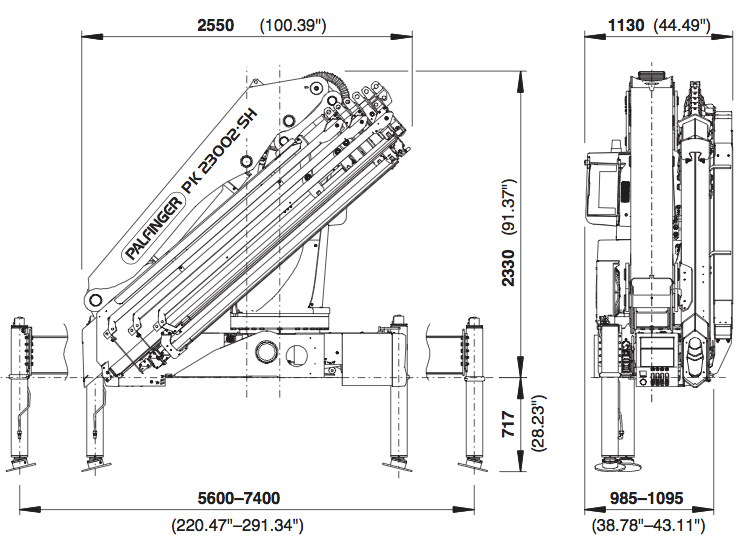

| Max. lifting moment | 21.9 mt |

| Max. lifting capacity | 6200 kg |

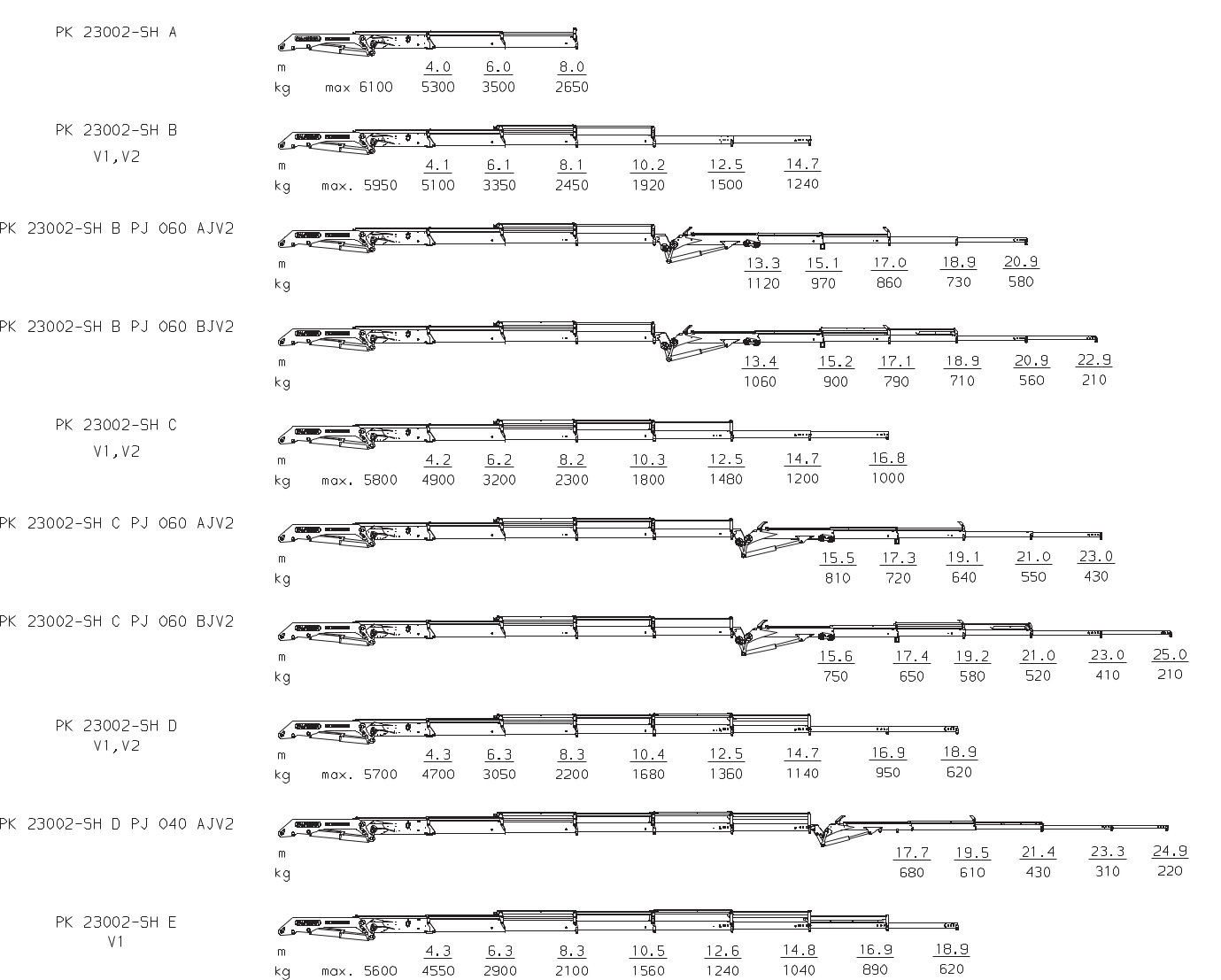

| Max. hydraulic outreach | 17.1 m |

| Max. manual outreach | 19.1 m |

| Max. outreach (with fly jib) | 25.2 m |

| Slewing angle | ∞ |

| Slewing torque with 1 gear | 2.3 mt |

| Stabilizer spread (std) | 5.6 m |

| Fitting space required (std) | 0.99 m |

| Width folded | 2.55 m |

| Max. operating pressure | 365 bar |

| Pump capacity | 75 - 100 l/min |

| Dead weight (std) | 2549 kg |

Cranes shown in the leaflet are partially optional equipped and do not always correspond to the standard version.

Country-specific regulations must be observed. Dimensions may vary. Subject to technical changes, errors and translation mistakes.

|

(mt) |

(m) |

(°) |

(mt) |

(MPa) |

(l/min) |

(kg) |

(mm) |

(mm) |

(mm) |

|

|---|---|---|---|---|---|---|---|---|---|---|

| 21.2 | 8.2 | ∞ | 2.3 | 36.5 | 75-100 | 2549 | 2330 | 2550 | 985 | |

| 20.7 | 10.4 | ∞ | 2.3 | 36.5 | 75-100 | 2717 | 2330 | 2550 | 985 | |

| 20.3 | 12.6 | ∞ | 2.3 | 36.5 | 75-100 | 2852 | 2330 | 2550 | 1050 | |

| 20.0 | 14.9 | ∞ | 2.3 | 36.5 | 75-100 | 2976 | 2330 | 2550 | 1095 | |

| 19.6 | 17.1 | ∞ | 2.3 | 36.5 | 75-100 | 3093 | 2330 | 2550 | 1095 |

The outreaches stated are with a boom angle of 20° and are therefore not the maximum. When using mechanical boom extensions, the loads shown on the charts need to be reduced by the weight of these extensions.

PALFINGER SERVICES

Brochures

You are currently on the PALFINGER United Kingdom page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?