Multi

HT 160

Single Axle

Higher Performance

- Reduced dead weight (-10%) while keeping the lifting and tipping capacity unchanged at 16,000 lbs.

Easy Installation

- The new subframe design, featuring a raised front cross member, suits many trucks.

- Quick and easy installation

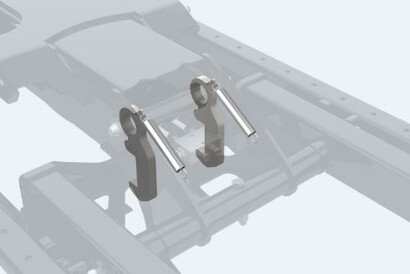

- Standard Advanced Mounting (SAM)

- POP (PALFINGER Origin Protection) Painting and surface treatment — best protection for our customers' investment value over the unit's lifetime.

User-Friendliness

- Adjustable hook height (36"/54")

- Greaseless bushings minimize maintenance

- New hook shape — allows for easier connection to the container bar

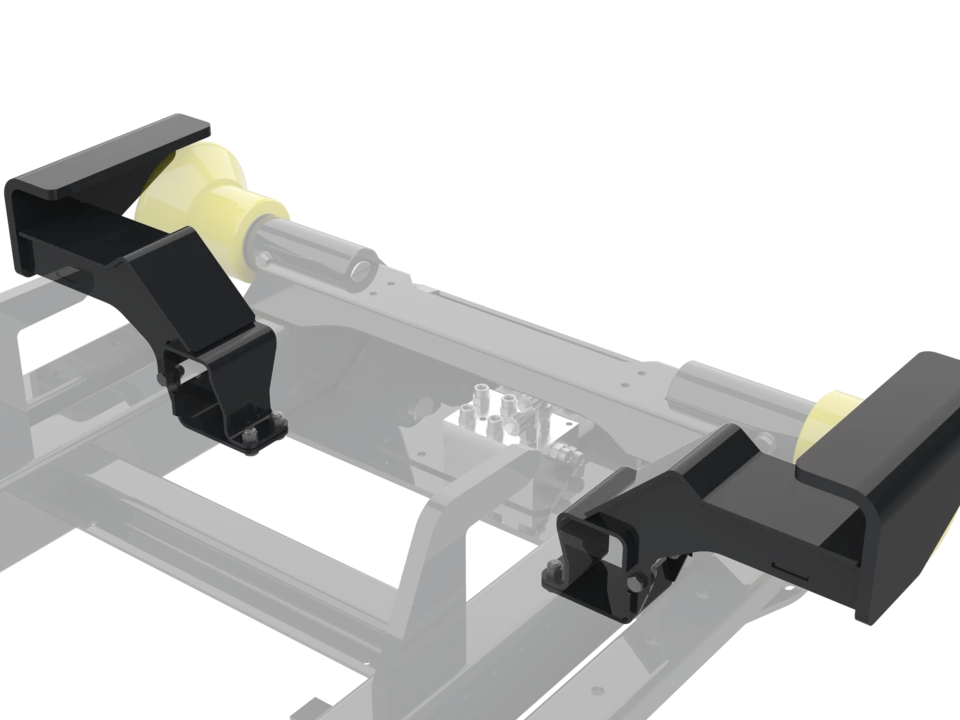

- Flexible "clamp-on" slide-through container hold-down brackets

Container Locking System

- Equipped with mechanical locking hooks welded to the tipping frame.

- The “clamp-on” slide-through container hold-downs are to be added on request and can be easily positioned to the customer's demand.

User-friendliness: flexible positioning of the slide through hold-down brackets.

Main Control Valve

The SLD3 range features a single-speed control.

- The SDM110 main valve has a “monoblock” design with a direct electric spool activation (no compressed air required).

- Equipped as standard with three hydraulic functions. Optionally up to five functions are possible.

Optional feature “Softstop”:

- A hook loader of this capacity range is now available with the “soft-stop” feature for the first time. This well-known feature from only heavy-duty hook loaders slows down the bin 5° before it lands onto to base frame. This reduces the stress on the structure of the hook loader and the chassis frame.

"Spoon Effect" Hook Shape

This new hook arm design features a new “spoon effect” hook shape, simplifying the connection to the bin. It allows the pickup of the bin by just lifting the arm from underneath the container ring.

- Equipped as a standard with a mechanically adjustable hook height (36”/54”)

- Higher performance due to fewer limitations of hook heights

- User-friendly due to easier connection to the bin.

Highlights

Easy Drive Control System

Easy Drive control offers an easy and reliable in-cab command for hook loader operations. There are two different sizes are available with three or five functions.

The controller is connected by a thin CAN BUS cable and is programmed directly via the handset. Two LEDs are used for status indication and transport position monitoring. An acoustic warning is embedded in the cab control as well.

- Hook loader operation is activated via the in-cab control—no need for PTO signal.

- Auto power off the control system if the unit is not used for more than three minutes.

- The in-cab controller has a magnet to position it to the driver’s liking.

| Lift / DumpCapacity (lb.) | Optimum CA (in.) | Min. GVWR (lb.) | Hooklift length | Operating Pressure (PSI) | |

|---|---|---|---|---|---|

| 16000 | 120 | 22500 | 140 | 4500 | |

| 16000 | 108 | 22500 | 128 | 4500 |

| Lift / DumpCapacity (lb.) | Optimum CA (in.) | Min. GVWR (lb.) | Hooklift length | Operating Pressure (PSI) | |

|---|---|---|---|---|---|

| 7257.5 | 2.7 | 10205.8 | 3.3 | 31 | |

| 7257.5 | 2.7 | 10205.8 | 3.3 | 31 |

New Subframe

Speeds up the installation and ensures a proper fixation on the most common chassis.

- The side and top row of holes enable bolted fixation

- Free holes at the front crossbeam area

- The front cross beam is raised up just over 2.5 inches

- Collision with the gearbox is prevented

- The subframe is designed with a bi-point cinematic to ensure an optimized tipping capacity

Grease-Free Bushes

The bushes used are composed of compound material, enabling grease-free usage.

Reliability

- Compound bushes duration tests are making possible the extension of this technology.

Reduced Maintenance

- In total, 12 grease points are removed

New Top-Mounted Oil Tank

- Volume of 30L—it is to be noted that this tank will increase the installation length of the unit by 6”.

- Alternatively, the already-known 50L oil tank for chassis installation can be used.

Easy installation: Fully bolt-on solution to existing holes in the base frame of the hook loader

Rear Rollers

New design— the shaft retaining system is modified to two screws and a plate to be more service friendly.

Control Box Position

The control box is positioned in the middle left, and the main control valve is perfectly protected with a cover made of treated steel with higher scratch resistance.

You are currently on the PALFINGER Latinamerica page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?