Cantilever

MBB C 2000 L

MBB C 2000 L

Tail Lift

- Optimum ratio of dead weight to payload = greater transport capacity

- Lifting capacity of 2,000 kg with 750 mm load distance

- Variable lifting mechanism with five available lifting arm lengths for all common attachment situations

- Design with aluminium or steel platform

- Wide range of options and equipment variants

Cantilever

Experience the product features

Außenseite

- Steel platform with powder-coated rearside (in a RAL colour)

- Aluminium platform with wet-painted rearside, with or without tip (in a RAL colour)

- Aluminium platform anodised (up to 2000mm height)

- Horizontal folding Aluminium platform for cantilever lifts (max. width 2520mm)

- Mounted advertisement panel for steel platform (not for FerroTop)

Lifting gear standard

- Cylinders with protection bellows and tubes

- All steel components in KTL

- Mounting brackets

- Lifting gear powder-coated (in RAL9011 or NOVA grey)

- Lifting gear micro-galvanised 750er

- Bolt-on mounting brackets (not LZ/SZ models and MBB C 500 VAN to MBB PTC 750 S)

- Welded mounting brackets (please provide chassis dimensions)

- Hydr. Stabiliser, large, installed, pair (double-acting cylinders)

- Mechanical stabilisers, large, lose, pair

- Preparation for central lubrification C 1000 S - C 3000 S

| Lifting capacity | 2000 kg |

| Main beam | 180 x 180 mm |

| Lifting gear hydraulics | 2 lifting cylinder / 2 tilting cylinder |

| Platform overlap with floor | - 63 mm |

| Lift arm pitch /Lift arm length | 1300 mm |

| Load centre - lengthwise | 750 mm |

| Load centre - across center | Central 50% of rated load on one side |

| Inclination angle of the platform | +90° to -10° |

| Platform type | Platform width | platform height | Dead Weight | Dead Weight | |

|---|---|---|---|---|---|

| alu | 2500 | 1800 | 517 | - | |

| alu | 2500 | 2100 | 539 | - |

The specified weights apply to the lightest platforms of the corresponding height. Dimensions may vary. Subject to technical changes, errors and translation mistakes.

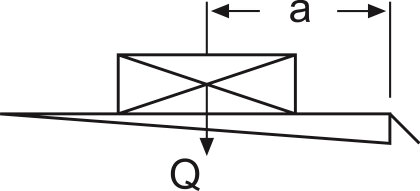

| a (mm) | Q (kg) |

| 750 | 2000 |

| 900 | 1650 |

| 1100 | 1300 |

| 1600 | 950 |

| 2400 | 600 |

Feasibility study

Webtool for automatic feasibility study for C- Type Lifts

Here you can create your feasibility study drawing online. For an extensive range of vehicles, quickly and without obligation

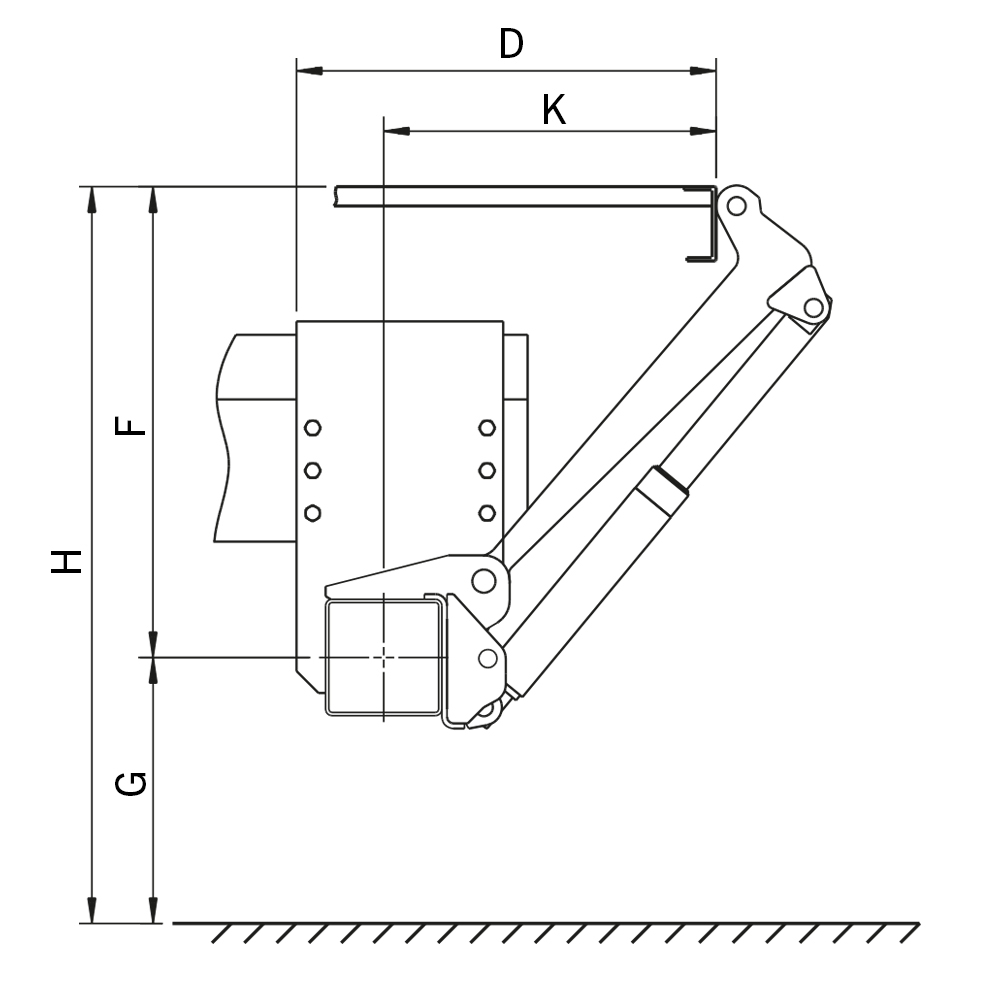

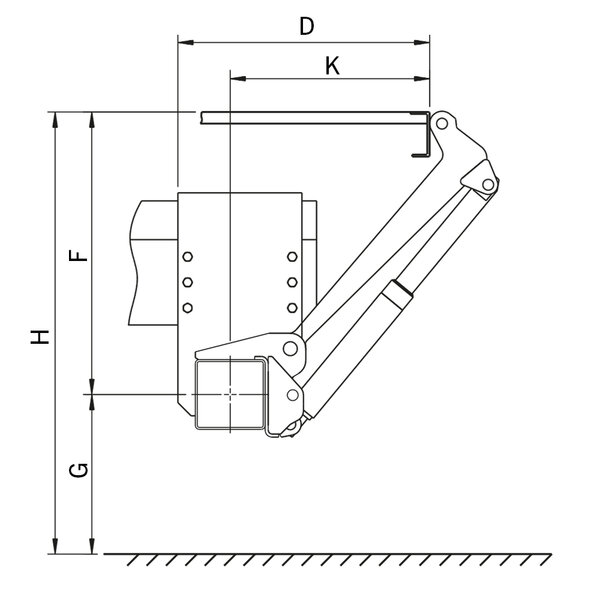

Dimensions

| Lift arms (in mm) | 750 | 800 | 850 | 950 |

| H (max.) Loading height unloaded | 1340 | 1416 | 1505 | 1657 |

| H (min.) Loading height loaded | 1127 | 1165 | 1204 | 1281 |

| F (max.) Middle of main beam to upper edge of loading floor | 858 | 904 | 967 | 1061 |

| K (min.) at dimension F (max.) | 413 | 434 | 410 | 444 |

| D (min.) Installation space (min.) | 563 | 584 | 560 | 594 |

| D (max.) Installation space (max.) | 752 | 785 | 816 | 880 |

| F (min.) | 742 | 780 | 819 | 896 |

| K (max.) at dimension F (min.) | 602 | 635 | 666 | 730 |

Downloads

Brochures

Please choose your region, country and language

PALFINGER Worldwide

You are currently on the PALFINGER United Kingdom page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?