Cantilever

MBB C 1000 L

MBB C 1000 L

• Universal eco mounting brackets for multiple different vehicles

• Three-piece underrun protection device

• Ball head coupling available (retrofit must be welded)

• Available with AluLite 30/40L or Ferrostar (steel) platform

Experience the product features

Außenseite

- Steel platform with powder-coated rearside (in a RAL colour)

- Aluminium platform with wet-painted rearside, with or without tip (in a RAL colour)

- Aluminium platform anodised (up to 2000mm height)

- Horizontal folding Aluminium platform for cantilever lifts (max. width 2520mm)

- Mounted advertisement panel for steel platform (not for FerroTop)

Lifting gear standard

- Cylinders with protection bellows and tubes

- All steel components in KTL

- Mounting brackets

- Lifting gear powder-coated (in RAL9011 or NOVA grey)

- Lifting gear micro-galvanised 750er

- Bolt-on mounting brackets (not LZ/SZ models and MBB C 500 VAN to MBB PTC 750 S)

- Welded mounting brackets (please provide chassis dimensions)

- Hydr. Stabiliser, large, installed, pair (double-acting cylinders)

- Mechanical stabilisers, large, lose, pair

| Lifting capacity | 1000 kg |

| Main beam | 180 x 180 mm |

| Lifting gear hydraulics | 2 lifting cylinder / 2 tilting cylinder |

| Platform overlap with floor | -44 mm |

| Lift arm pitch /Lift arm length | 1,100 / 1,320 mm |

| Load centre - lengthwise | 600 mm |

| Load centre - across center | Central 50% of rated load on one side |

| Inclination angle of the platform | +90° to -10° |

| Platform type | Platform width | platform height | Dead Weight | Dead Weight | |

|---|---|---|---|---|---|

| alu | 2400 | 1600 | 282 | - | |

| alu | 2400 | 1700 | 289 | - | |

| alu | 2400 | 1825 | 295 | - | |

| steel | 2400 | 1509 | 357 | - | |

| steel | 2400 | 1209 | 312 | - | |

| steel | 2400 | 1809 | 402 | - |

The specified weights apply to the lightest platforms of the corresponding height. Dimensions may vary. Subject to technical changes, errors and translation mistakes.

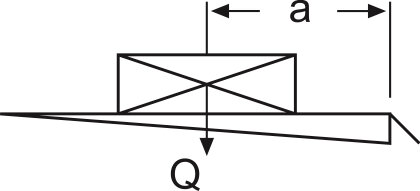

| a (mm) | Q (kg) |

| 600 | 1000 |

| 750 | 800 |

| 950 | 600 |

| 1400 | 400 |

Feasibility study

Webtool for automatic feasibility study for C- Type Lifts

Here you can create your feasibility study drawing online. For an extensive range of vehicles, quickly and without obligation

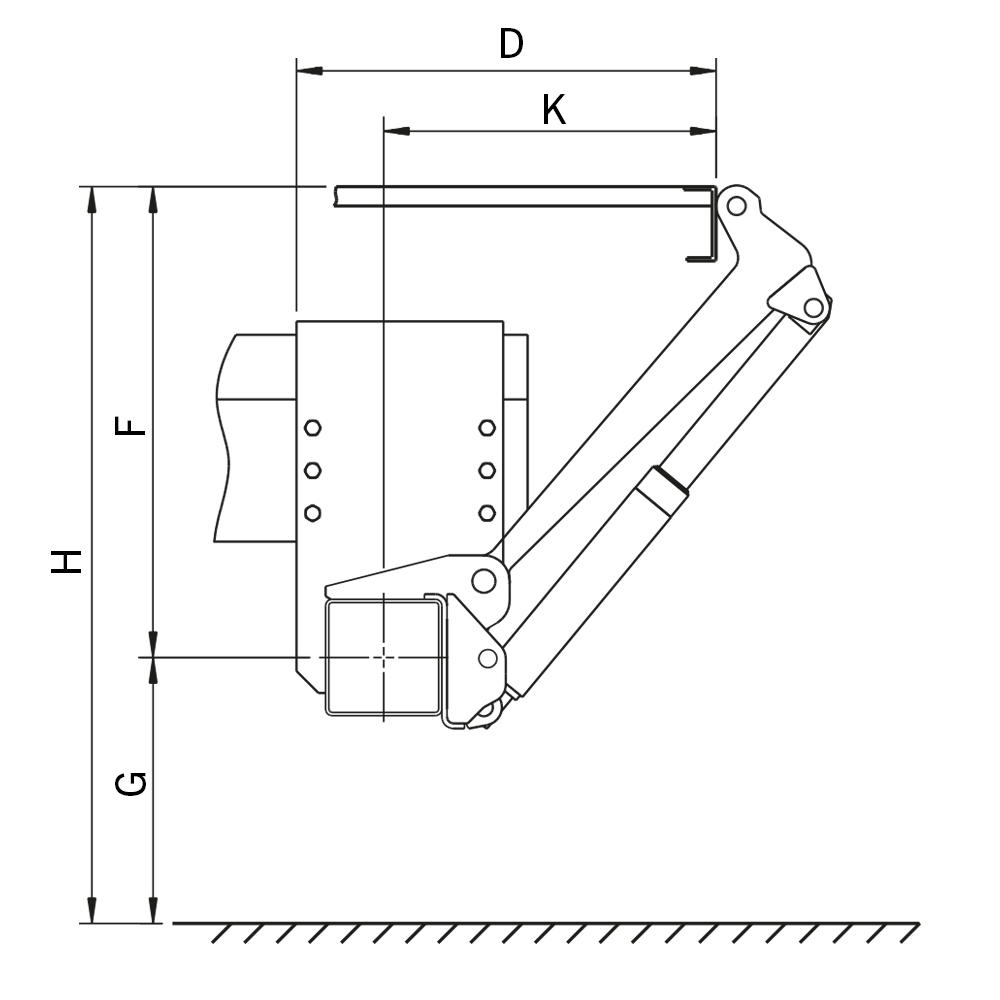

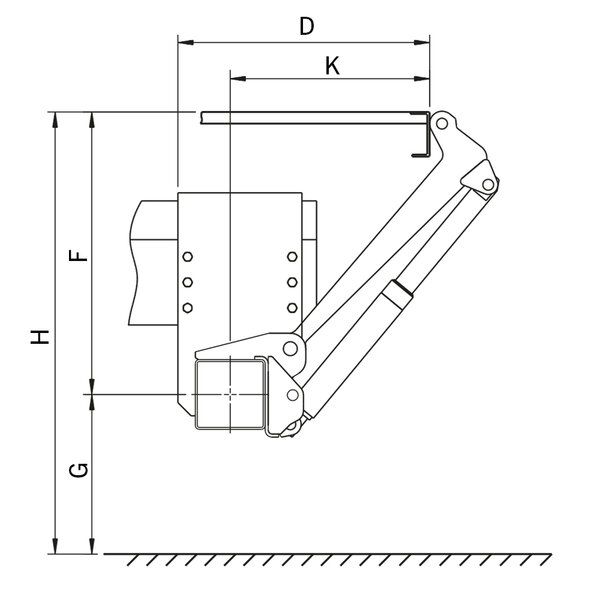

Dimensions

| Lift arms (in mm) | 600 | 700 |

| H (max.) Loading height unloaded | 1100 | 1210 |

| H (min.) Loading height loaded | 750 | 830 |

| F (max.) Middle of main beam to upper edge of loading floor | 620 | 650 |

| K (min.) at dimension F (max.) | 467 | 592 |

| D (min.) Installation space (min.) | 617 | 742 |

| D (max.) Installation space (max.) | 802 | 871 |

| F (min.) | 420 | 500 |

| K (max.) at dimension F (min.) | 652 | 721 |

Brochures

You are currently on the PALFINGER United Kingdom page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?