Multi

HT 500

Tandem Axle

Experience the next generation of heavy-duty hookloaders designed specifically for the North American market. Engineered with a focus on safety, comfort, and durability, the HT 500 is set to redefine your hauling experience.

This model features a telescoping (54 or 61 ¾ inch) jib with dual main cylinders.

50,000 lbs. capacity

PRO ACTIVE DRIVE (PAD) REMOTE CONTROL

Intuitive and interactive remote control designed for complete cab comfort, allowing the operator to load and unload containers without leaving the cab.

Customizable to accommodate single operational add-ons such as tarper, salt spreader, and snow plow, ensuring a seamless workflow.

Optional Features:

- Automatic Cycle: Effortlessly load and unload with a single joystick push.

- Rapid Motion: Enjoy a 30% increase in extension speed for empty containers.

REMOVABLE & ADJUSTABLE CONTAINER SLIDES

- Easily adjust the container slides to accommodate various container lengths, providing flexibility for your hauling needs.

- Standard container rests are constructed with full-cast steel, ensuring long-lasting performance and stability.

- Softsliding container rests feature highly abrasion-resistant plastic guide pads, which result in smoother movements, reduced noise, and minimize wear on container rails.

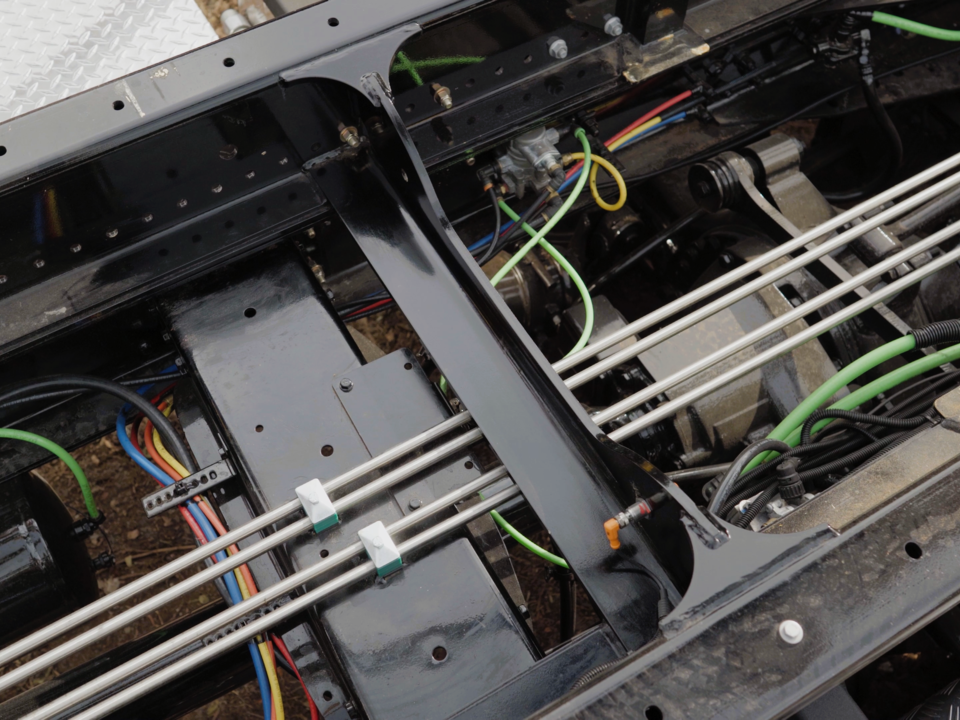

NEW SUBFRAME DESIGN

The new subframe design increases stability, especially in tipping operations.

- X-Beam provides increased resistance against chassis torsion, increasing the vehicle's lifetime

- Front Cross Beam reduces the risk of interference with truck engine or gearbox components

- Improved Mid-Cross Beam Design

- Stronger Rear Cross Beam Design

Highlights

IMPROVED HOOKARM DESIGN

Features an enhanced hook arm design, offering greater strength for easier hook height adjustment, smoother engagement with container bars, and increased safety.

- A new safety latch ensures secure locking of the container baler into the hook, preventing any bouncing or accidental disengagement.

- The addition of a new casted corner part with an integrated rubber buffer provides a dedicated touchpoint for the container, enhancing durability and reducing wear.

- With a hook height adjustment range of 54” to 61 3/4”, facilitated by a new mechanical stop, achieving the desired hook height is now simpler and more precise.

| Lift / DumpCapacity (lb.) | CA Range (in.) | Min. GVWR (lb.) | Min RBM (in. lb.) | Hooklift length | Clear Frame Rail (in.) | Body Length Range (ft.) | Optimum Body Lenghts (ft.) | Jib Height (in.) | Jib Action | Max. Dump Angle | Pivot | # of Lift / Dump Cylinders | Operating Pressure (PSI) | Pump Type | Fitting Hoses | Shipping Weight (lb.) | Paint | Construction | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50000 | 185-195" | 64000 | N/A | 237 | 242 | 16-22' | 20-22' | 54'' & 61.75'' | Telescopic | 48 degrees | Dual | 2/2 | 4500 | Piston - Direct mount | JIC/SAE | 5280 | Finish Coat | A514 (T-1) | |

| 50000 | 185-195" | 64000 | N/A | 237 | 242 | 16-22' | 20-22' | 54'' & 61.75'' | Telescopic | 48 degrees | Dual | 2/2 | 4500 | Piston - Direct mount | JIC/SAE | 5280 | Finish Coat | A514 (T-1) |

| Lift / DumpCapacity (lb.) | CA Range (in.) | Min. GVWR (lb.) | Min RBM (in. lb.) | Hooklift length | Clear Frame Rail (in.) | Body Length Range (ft.) | Optimum Body Lenghts (ft.) | Jib Height (in.) | Jib Action | Max. Dump Angle | Pivot | # of Lift / Dump Cylinders | Operating Pressure (PSI) | Pump Type | Fitting Hoses | Shipping Weight (lb.) | Paint | Construction | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 22680 | 185-195" | 64000 | N/A | 602 | 615 | 4.88-6.70 m | 6.10-6.71 m | 137.16 cm & 156.8 cm | Telescopic | 48 degrees | Dual | 2/2 | 310 | Piston - Direct mount | JIC/SAE | 2395 | Finish Coat | A514 (T-1) | |

| 22680 | 185-195" | 64000 | N/A | 602 | 615 | 4.88-6.70 m | 6.10-6.71 m | 137.16 cm & 156.8 cm | Telescopic | 48 degrees | Dual | 2/2 | 310 | Piston - Direct mount | JIC/SAE | 2395 | Finish Coat | A514 (T-1) |

- Dual Pivot Design

- Flexible design with true dumping capabilities

- High Pressure Hydraulics (3,600 psi to 4,500 psi)

- Allows system to take advantage of smaller cylinders, sving you weight and increases your available payload.

- Container Hold Downs

- Inside on T-12, PHT-16, and T-20 models

- Outside on all other models

- Adjustable (forward and back) on PHT-22

- Dual Lift/Dump Cylinders

- Steady and secure handling of bodies during loading, unloading and dumping operations

- Dual Counter Balance Valves

- Safety feature providing power up and power down

- Accessible and serviceable

- Dual Rear Rollers standard on T-40 models and up

- Soft Stop Landing standard on T-29 and up

- Telescopic jib

- High strength steel supports

- No wearable/replaceable pads

- Adjustable Height Jib

- Hydraulic optional on T-29S, T29-M - 36" and 54"

- Manual standard on T-40 and up - 54" and 62"

- Inside Controls

- Greasable with bronze bushings at all pviot points

- High strength steel frame - Z rail design

- Safety sensors

- Jib sensor ensures the jib cannot retract while in dump mode (all models)

- Dump latch sensor ensures the latches are fully engated (all models)

- Soft stop sensor ensures gentle landing of body after dumping (T-29 and up)

- 3-Year Limited Warranty

You are currently on the PALFINGER Canada page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?